|

Inside

Model M

Example:

P/N 1391401

( Earlier type)

|

Got a junk Model M P/N 1391401 made in 1987.

Condition of upper actuator panel is really

bad but every buckling springs and hammers inside actuators are all

fine. I decided to disassemble the base assembly to pull out

hammers. I also wanted to know if the assembly can be used

again, I mean if it is possible to repair Model M .

|

|

|

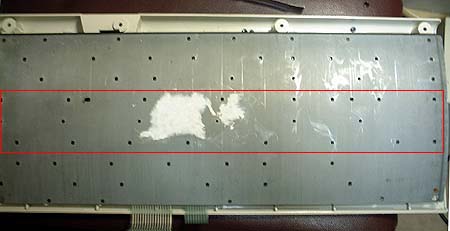

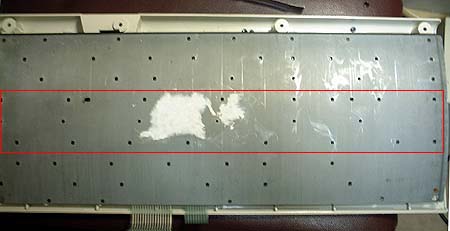

All the melted

plastic studs were cut off so that the steel plate can be removed

from the upper actuator panel. |

|

|

|

Membrane sheets are placed like above. |

|

|

|

|

Upper and lower

sheets with conductive tracks are separated by a translucent

membrane sheet which has holes right at the position of each

contacts.

The thickness of the middle translucent sheet gives a gap which

separates contacts on the upper and lower membrane sheets with

signal tracks.

Observing a later model 42H1292, layout of membrane sheets

seems slightly different from 1391401. The most closest membrane

sheet to the actuator panel is directly pressed to the control

PCB. The signal tracks on the lower membrane sheet are also

pressed to the upper membrane sheet and the each signals on the

lower sheet are led to PCB through upper membrane sheet. |

|

|

|

| Actuator panel with hammers is covered with a

rubber sheet. |

Close up of hammers

|

|

|

|

| Hammer units used in this model are translucent

type. Some models use black hammers |

| Comparison ;

Hammer and Actuator of Model F |

|

|

|

|

Hammers used in Model F are larger that those of

Model M.

Every hammers hit the main PCB directly when each keys are

pressed.

The hammer is not a conductive material. You can easily confirm

it using a ohm meter. |

|

Simple spill proof design |

|

|

|

There are vinyl tubes at the both

side of upper panel to prevent dusts or liquid. The

upper and lower ends of actuator panel is firmly pressed to the

bottom metal plate by plastic studs ( upper end of studs melted at

the surface of the steel plate and act as "rivets" ) .

A rubber sheet in

between the actuator panel and the steel plate acts as a sealer

and it protect membrane sheets.

Please remind, above two pictures are actuator plate of

1391401. The spill-proof design of a later model such as 42H1292 is

a bit different from

1391401. |

|

|

|

Close up of a stud ( rivet )

there are more than 60 of plastic studs inside the actuator panel. These

studs

act as keys to place membrane sheets and rubber sheet

properly and at the same time each studs is used as a rivet to

press the plate firmly to base steel plate.

In order to re-use the plate after changing hammers or cleaning

membrane sheets, cut off some studs and drill holes

right at the base of each studs.

I did it for my 42H1292 . Do you want to try ?

Well, read this section

|

|